Services

As a company that thinks and acts responsibly in all respects, Matulka electronic attaches great importance to continuous growth in healthy dimensions. With a continuous improvement of all processes, the further development of our employees and future-oriented investments in equipment and the production environment, our company achieved in its more than 25-year-old existence a steady increase in turnover, which develops parallel to the number of employees positevely.

Due to the expansion of capacities in the new course of the new construction in 2000 and an optimized material purchase from 2003, a significant and permanently positive sales development could be achieved. Our goal is to further expand our portfolio and our range of services with the best services and satisfied customers.

The following services are an excerpt of our complete range of Services:

SMT-assembly

We have dealt with the topic of SMT (surface mounted technology) since 1986. As a result, we have developed expertise and perfected our manufacturing technology.

We always employ the latest technological developments through continual investments in technical facilities and control systems.

We work with Siplace machines that permit exact placement of all component sizes from 0.4 x 0.2 up to and including 55 x 55 mm. By combining high-quality machines from other high-profile manufacturers, we have several production lines with different configurations at our disposal.

THT-assembly

In 1974, THT (through hole techology) was the only technology used for assembling electrical modules.

Matulka electronic has nearly four decades of experience with this proven method. Two technical departments place and assemble modules by hand. Splash bath or selective soldering systems are available for realising soldering processes. At the same time, manual soldering methods are also utilised.

The best result determines the selection of the most sensible and economical combination of processes.

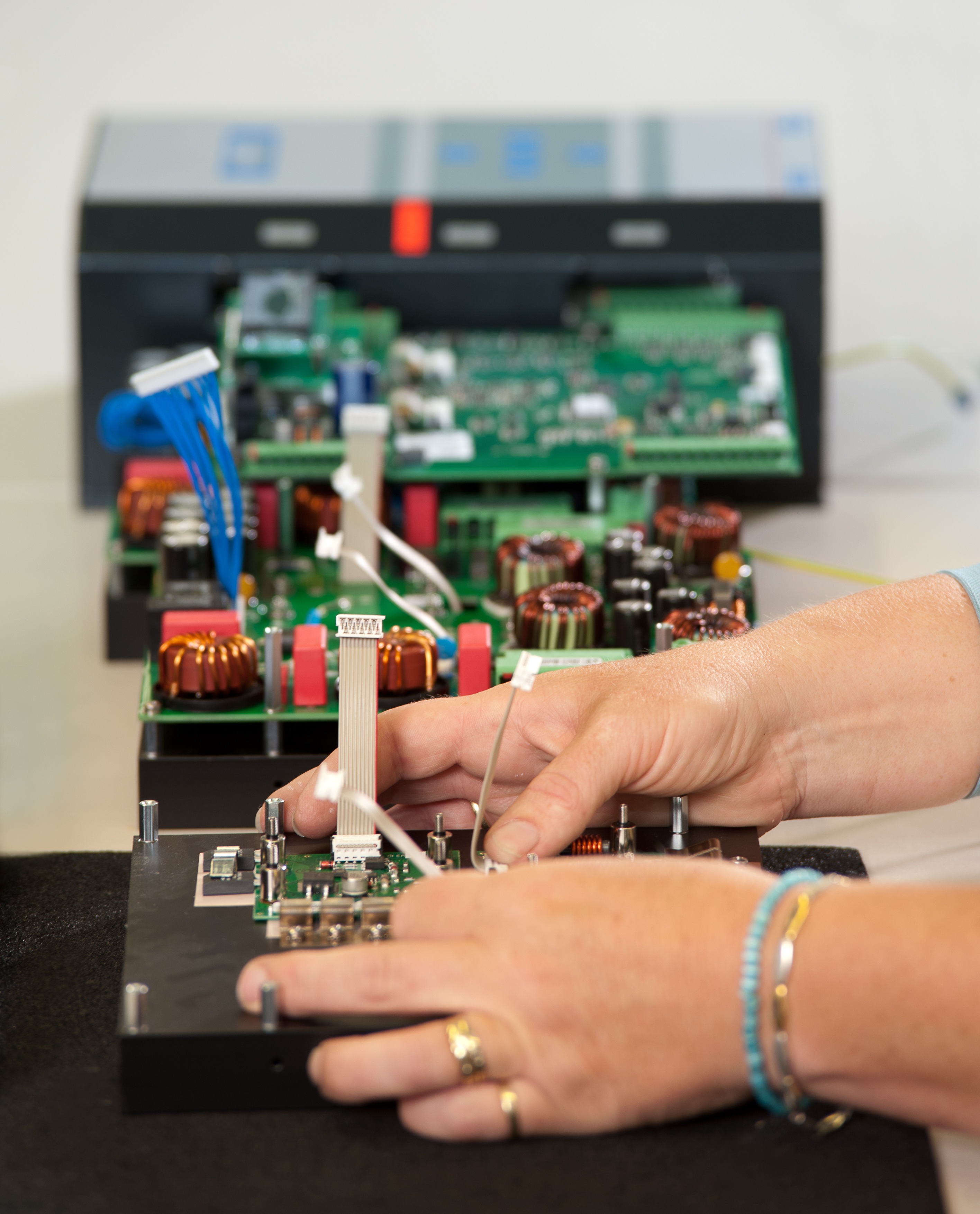

Device assembly

In the scope of our manual manufacturing, we assemble not only your circuit boards, but also complete electronic equipment in accordance with your specifications.

We also have long-time experience with large high-profile companies in this area, for whom we defined customised production and delivery processes.

Test & check

We ensure compliance with our high standards by employing a series of effective test procedures. They include: optical inspections under a microscope, automatic optical inspection (AOI) with an angled view, the use of specific test equipment from customers, function test units (FKT) or in-circuit test equipment (ICT) with module-specific test adapters.

Painting & Casting

Module protection against external influences, such as moisture and foreign substances is playing an increasingly important role. For that reason we have dealt extensively with the subject and offer you with the Protecto from Rehm a state-of-the-art functional system.

According to customer specifications, up to four different media can be applied to the module in a single operation, allowing, for example, underfilling of components, delineation against paint entry by forming a so-called dam and selective painting of individual areas in the shortest possible time and with the highest precision. This way, every product is optimally protected according to the requirements.

Material management

Many years of experience in electronics purchasing and a very good relationship with the usual distributors as well as directly to numerous manufacturers put us in the position to achieve very good price-performance-ratios for our customers. Because of our contact with globally operating companies we are also able to procure any hard-to-find or even discounted components at short notice.

Another advantage for our customers is our stock of numerous items which ensures that we have a large part of the required components available for production at short notice.

The PCN management, which is widely use in electronics, ensures that we are informed about changes to components. As a result, we can pass on this informations to our customers and are able to react to new circumstances immediately.